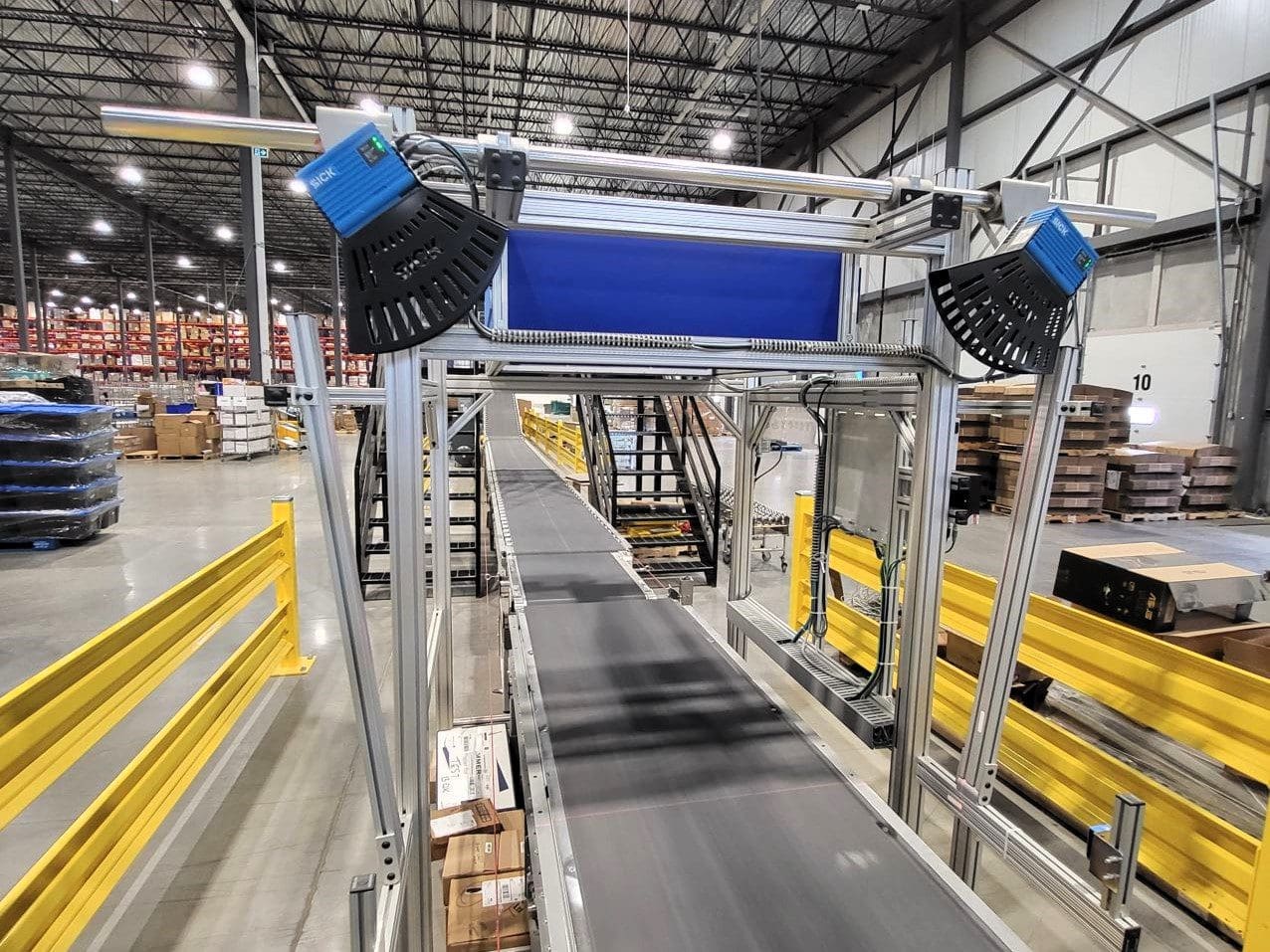

|Dimensioning

|Weighing

|Scanning

Transform the accuracy and speed of your material handling processes. Explore how our systems work to provide a seamless logistics workflow.

What is Dimensioning, Weighing & Scanning (DWS)

Dimensioning, Weights, and Scanning (DWS) systems are sophisticated solutions designed to optimize logistics processes by providing accurate measurements, weight verification, and efficient barcode scanning. Mainway Handling’s DWS systems offer real-time data collection, ensuring compliance, minimizing errors, and enhancing overall logistics efficiency.

Benefits

of our DWS systems

Ensure precise dimensional measurements, weight verification, and barcode scanning for each item.

Meet shipping regulations with accurate data, minimizing the risk of compliance issues.

Tailor the system to the specific requirements of your facility to accommodate package sizes and types.

Access real-time data and analytics for insights into logistics performance and areas for improvement.

What We Integrate

Designed for higher speed, providing measurements of dimensions and weight as packages move rapidly on a conveyor. Suited for very high-speed environments, such as express parcel sorting facilities.

Efficiently used in automated warehouses where seamless integration of sorting and measurement processes is crucial. DWS functionality is integrated into automated sortation systems, allowing for simultaneous sorting and measurement of packages.

Our DWS systems utilize laser technology to measure the length, width, and height of packages with precision. As packages move through the system, lasers automatically scan and capture the dimensional data of each item.

Ideal for warehouses with dynamic workflows, allowing for measurements during picking, packing, and other mobile operations. Mobile DWS systems can be mounted on forklifts, carts, or other mobile equipment, providing on-the-go measurement and weighing capabilities.

We tailor the DWS system to your facility’s unique needs, ensuring optimal performance and accurate shipping cost

How We Integrate

The system verifies weight and dimension data against predefined parameters, ensuring accuracy. Mainway Handling’s DWS systems provide data analytics capabilities, allowing for insights into shipping patterns, packaging efficiency, and compliance metrics.

As items move through the warehouse, they undergo scanning and identification processes. This can involve barcodes, RFID tags, or other tracking mechanisms. Mainway Handling’s advanced scanning technology ensures accurate identification of each item in real-time.

Automated conveyors and sorters carry items to their designated locations with precision. This minimizes manual handling, reduces the risk of errors, and increases overall throughput.

Throughout the sortation process, Mainway Handling’s systems provide real-time tracking and reporting. This visibility allows for monitoring the status of items, identifying potential issues, and making data-driven decisions for continuous improvement.

No thumbs on the scales here!