Have Fun Studying Our Cases!

Learn how our systems have transformed warehouse operations.

Case Studies

Wisdom is not the accumulation of knowledge, but the application of it.

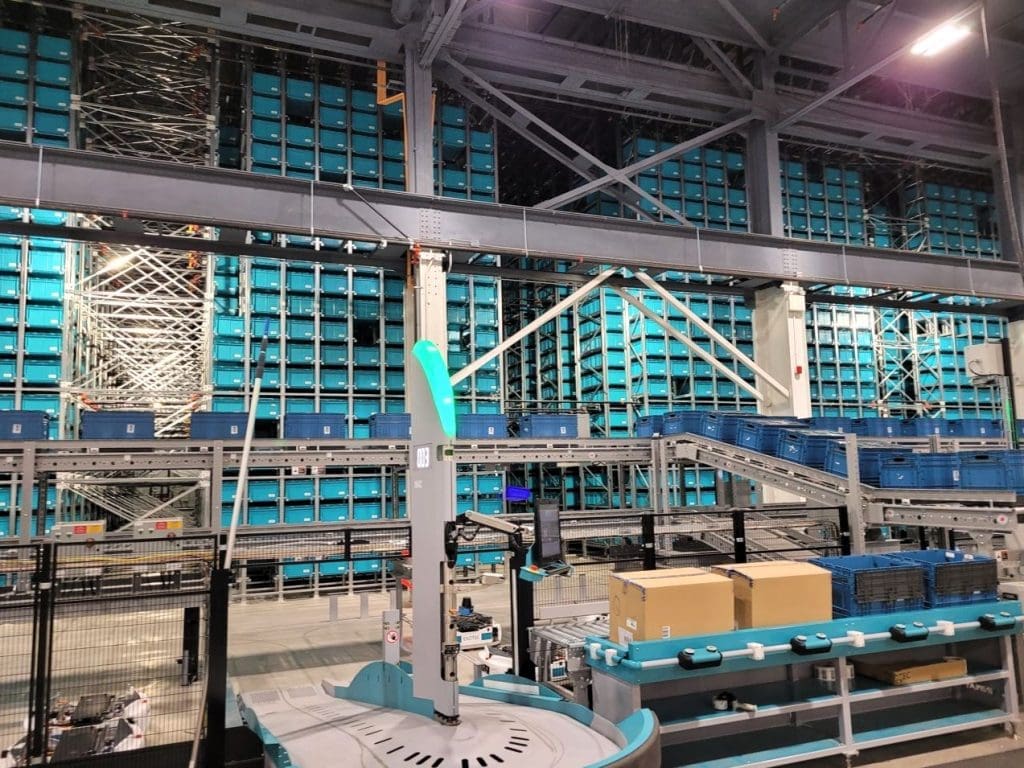

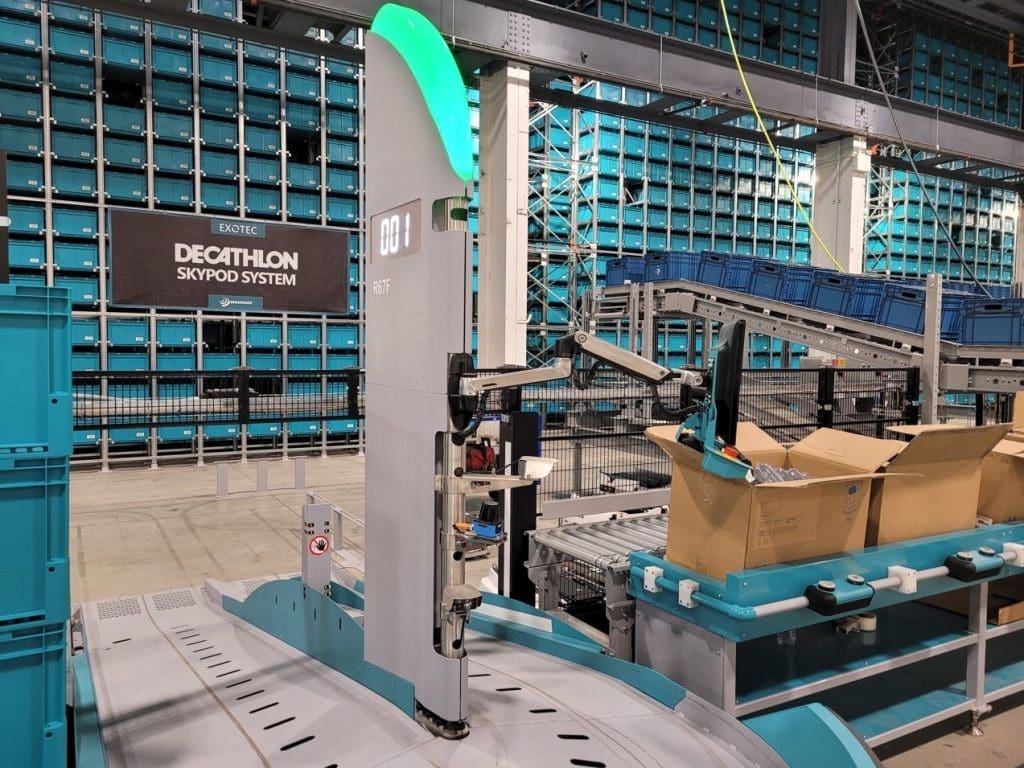

Industry: E-commerce | Retail

Systems: Exotec Skypod | Mainway MDR | Panther print and apply | Packsize X4

| Background

The European (French) based sporting goods company Decathlon was looking to expand their operations overseas in Canada. Wanting to transform and innovate the Canadian sporting goods market they sought an innovative solution to manage their growing inventory, ecommerce fulfillment and distribution network.

| Challenge

Due to the immense difference in rules and regulations between Canada, America, and Europe, Exotec was looking for a reputable and trusted company that can integrate this massive system and complete the puzzle. From our scales and weights system to Canadas different electrical and mechanical needs Mainway was chosen for our decades of experience and expertise in the Canadian market.

Mainway was relied on to navigate the regulations, integration, and installation of the conveyor portion of this expansive project. We fit right into the fold, being able to merge and integrate the various systems into one efficient, innovative, and cohesive system.

| Results

55 Robots

39ft Rack Heights

6 Pick Stations

Holds 30,000 SKUs

1500ft of conveyor

6x

productivity

11

stores served

7+

million orders delivered

Industry: E-commerce | Wholesaler

Systems: Mainway MDR | Eurosort Tray Sorter | Ryson Spiral

| Background

Book Depot is Canada’s largest wholesaler and retailer of bargain books. Established in 1985, they operate out of their 400,000 square foot distribution facility in Thorold, Ontario. With a staff of over 200 employees, 90,000 titles and 12 million copies in stock that seems to grow daily, they use automated order fulfillment equipment to ensure orders are shipped to customers quickly and cost effectively.

| Challenge

Book Depot’s rapid growth demanded a more efficient way to sort incoming inventory. Van Vliet then introduced a mechanical sorter to process their inbound product and he incorporated innovative technologies like conveyor routing and robotics to support the project.

Mainway was selected to provide the conveyor routing systems to connect all these components together, including the take-away conveyors from the mechanical sorter, additional zone diverts throughout the conveyor fulfillment system and a recirculation line to by-pass the shipping area and reduce the congestion in this area.

| Results

“The people at Mainway are attentive to our needs and have a genuine interest in solving problems for us. I really appreciate the level of service, support and advice that they offer.”

– Bill Van Vliet, CIO at Book Depot

30 million books sorted a year

7,200 units per/hr

7,000 sq/ft less floor space used

3x

increase in productivity

2/3

less time to process

99.6%

accuracy rate

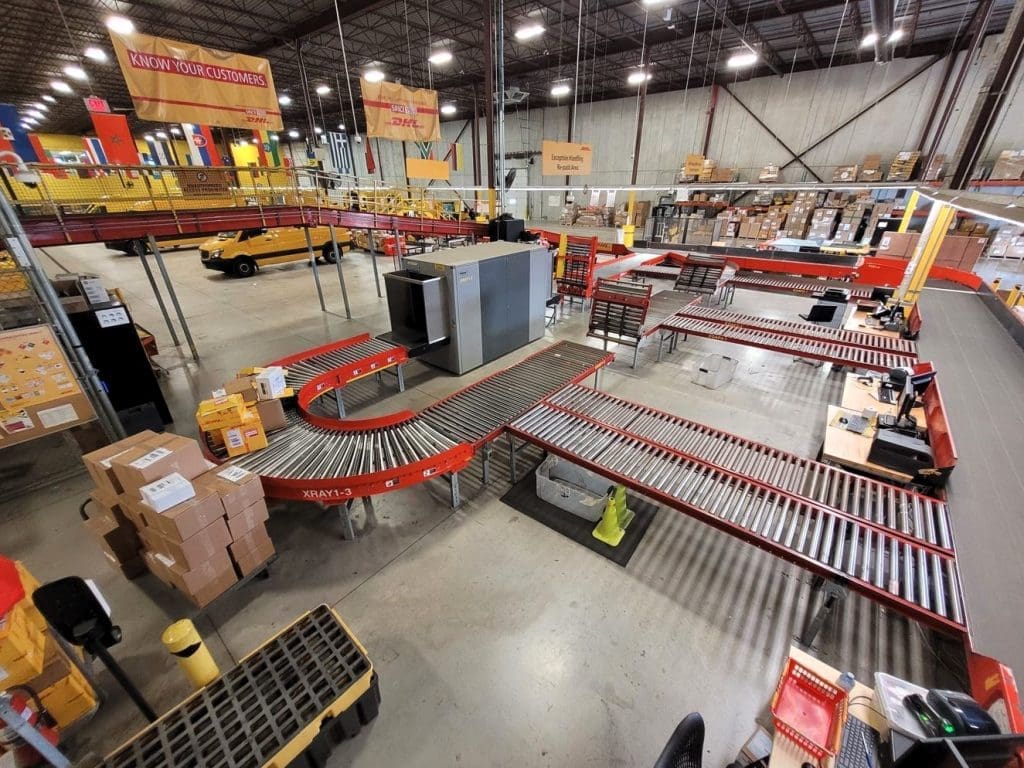

Industry: Freight & Parcel | Supply Chain | Logistics

Systems: Mainway Caster Decks | FMH Telescopic Conveyors | Pallet conveyors | Pallet turntables

| Background

DHL Express, a division of DP DHL, is a major international courier company serving over 220 countries across the globe. They offer a wide range of parcel and package services along with shipping and tracking solutions designed to meet the needs of every client.

| Challenge

DHL Express was looking for a single source integrator who could take a project from start to finish and manage all aspects of the project for their Hamilton Ontario expansion. Steve Vitella, Project Manager, recognized that there were few single source integrators in Canada and was looking for other options – which is how they discovered Mainway Handling. In addition, Mainway was also geographically close to DHL’s Hamilton location – making it simpler and easier to work with them on the project.

| Results

“Working with Mainway, the project was completed on time, on schedule and on budget. We have been working with Mainway ever since.”

– Steve Vitella, Project Manager for DHL Express

18

sites installed

We

maintain the sites

70+

million deliveries

Industry: Freight & Parcel | Supply Chain | Logistics

Systems: Interroll Cros Belt Sorter | FMH Telescopic Conveyors | Dimensioning and Scan tunnels

| Background

Loomis Express and Canpar was purchased by TFI International in 2011 and is a key member of the parcel delivery segment. Through these subsidiaries, TFI International is the leader in Canada’s transportation and logistics industry. TFI International provides a comprehensive and unique combination of capabilities, resources and geographical coverage in both domestic and transborder markets. Its companies operate in six well-defined business segments: Less than Truckload, Package and Courier, Small Parcel Delivery, Specialized Services (which includes transportation services, fleet management and personnel services), Specialized Truckload and Truckload.

| Challenge

TFI International along with their Canadian arm’s Loomis & Canpar were looking for a trusted supplier and vendor to design and install one of their essential west coast sorting HUB’s at 105,600 Sq. ft having the capability of handling at a high-peak of 8000+ packages an hour. Having built a solid relationship with Loomis and Canpar over several successful projects and installs, we were able to secure our largest project to date.

Moreover, Mainway Handling is located in the GTA of Ontario while this HUB was being built near the Calgary airport. This in itself poised a challenge onto itself, but given the high level of detail that needed on a project of this scale, Mainway was more then ready to meet the challenge head on.

| Results

Sorts 8,000 ppr

moves at 375 fpm

2 five-sided scan tunnels

7 DIM tunnels

4 video coding stations

7

induction lines

17

outbound doors

80

P&D van positions

| Gallery