7 benefits of working with an integrator that specializes in custom end-to-end solutions

Whether you are in the warehouse and distribution, automotive, food and beverage or freight and parcel industry, chances are you probably have a complex series of conveyors and other material handling processes in place. Achieving an integrated and efficiently engineered system that works smoothly, makes the most of your workspace and maximizes output is not an easy task – particularly if you are working with a mix of new and old, high-tech and low-tech and good old fashioned manual labour to perform your material handling tasks. The combinations can be endless.

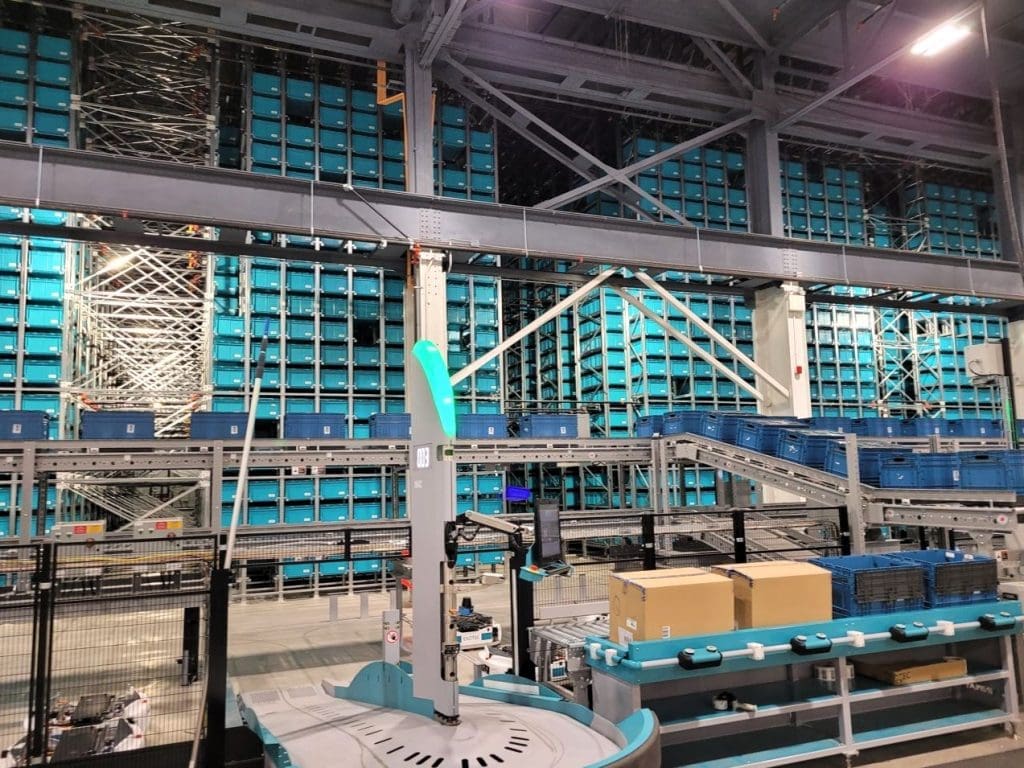

If we look at conveyors, for example, there are myriad types of conveyors, from motor-driven roller conveyors to belt conveyors to simple gravity conveyors – all of which might be equipped with sensors and controls to track and expedite the movement of your product. Your conveyor systems could be running side by side or they could be over/unders. They may even be equipped with gravity bin tippers or other elements required by your specific processes. There are multiple permutations, arrangements and elements that could be included in your conveyor system to achieve the results you require.

If you are looking to improve your system’s efficiency, update your facility, install completely new equipment or integrate new and old systems, now might be the time to merge all of your material handling systems into one end-to-end solution. Getting your conveyors, sorters, automated storage, selectors and robotics systems to work in harmony will not only improve the efficiency of your operations, it should also result in a positive impact to your bottom line.

It is important to keep in mind, however, whether you are implementing new equipment, upgrading your old system or combining them together, the integration of your material handling systems will take a great deal of knowledge, planning and custom engineering. With all of these factors to consider, looking to an outside integrator to deliver a turnkey solution for all of your material handling needs makes sense.

A good integrator can provide you with an engineered design to help you create a customized material handling solution, while working within your space confines, preferences and staying within your budget.

Here are 7 benefits of working with a professional material handling systems integrator:

- A good integrator will bring years of experience with extensive knowledge and expertise in the material handling industry – including the latest products and technologies available.

- By delegating the project to one party to undertake your systems integration, you avoid both internal and vendor confusion and conflicts.

- You can hold a single material handling systems integrator accountable for the entire project, regardless of the number of suppliers.

- You don’t need to invest in additional resources, such as time to chase down suppliers or trying to work out logistical obstacles.

- Experienced material handling systems integrators will take complete control of the design, installation and integration process and deal with all the technical issues.

- If you are making changes to, or customizing the system during implementation, it is easier to deal with one contact rather than several different suppliers.

- A good integrator will be able to integrate new equipment into your existing material handling system without interrupting your day-to-day operations.

Whether you are trying to cut labour costs, increase accuracy, improve output or reduce order processing time, choosing a custom integrator over a manufacturer will provide you with the flexibility you need to design the right solution for your needs. At Mainway, we are committed to providing you with an end-to-end turnkey material handling solution designed specifically to your requirements. We deliver an unprecedented standard of excellence in conveyor design, material handling, systems integration and advanced storage solutions.

Let’s talk today about getting your material handling system streamlined and profitable.

Comments are closed